Uncovering the Bittersweet Reality of This Low Glycemic Sweetener

Is agave syrup healthy? It's marketed as a healthy, natural, low-glycemic alternative to sugar. Most consumers are under the impression that agave syrup is minimally processed and made in a similar way to maple syrup—by poking a hole in the agave plant to collect the sap that oozes out, then boiling it to concentrate its sugars.

Decades ago, they would have been correct in believing that agave syrup is healthy, but the commercially available agave syrup found on supermarket shelves nowadays is entirely different. Natural whole foods such as sugar cane and monk fruit are significantly different from their ultra-refined and concentrated counterparts of white sugar and mogroside V powder mixed with erythritol. Processing a healthful whole food robs it of nutritious fiber and phytonutrients and may leave traces of toxic chemicals used in processing. The result is a profitable product, not food. (For more info, read my post Eat Like a Human, Not a Machine )

Aguamiel: Agave's Healthy, Low Glycemic Version of Maple Syrup?

Aguamiel is the sap from the agave plant. As the succulent reaches maturity (at least 5 to 15 years, depending on the species), it produces a giant flower stalk that can grow up to 30 feet tall. Collecting aguamiel involves cutting the stalk before it flowers, letting the plant rest for at least 1 to 3 months to concentrate its sugars, then collecting the sap twice daily for 2 to 8 months, until the plant dies. The traditional method of collection is by sucking the sap by mouth into a long gourd that has an opening on both ends. A modern alternative is to suck on a plastic hose to transfer the sap into a plastic bottle.

Aguamiel "honey water," has been prized for centuries in Mexico, serving as both a nourishing elixir rich in healthy probiotics and the foundation for pulque, a cherished fermented beverage in Mexican culture.

Heating aguamiel to evaporate the water and concentrate its sweetness was a historic way of making agave syrup, reminiscent of making maple syrup. This image is how healthy agave syrup is marketed nowadays.

However, since collecting aguamiel is a labor-intensive process, commercial agave syrup production involves hydrolyzing the piña (the core of the agave plant, which resembles a pineapple) due to its higher efficiency and yield. The starchy complex carbohydrates in the piña, mainly inulin, are broken down into simple sugars of glucose and fructose using heat, acid, or enzymes. The hydrolyzed syrup from certain species of agave can be fermented and distilled into mezcal or tequila.

Heat or Thermal Hydrolysis Processing: the Time-Honored Way

Roasting piñas in smoky underground pits is how mezcal has been made for hundreds of years. This method takes 3 days to a week—so only rare, artisanal tequilas are made this way.

Brick oven cooking with steam takes 36 to 72 hours. The highest-rated tequilas tend to be made this way, as the slow cooking creates caramelization and complex flavors.

Autoclaves, which are stainless steel pressure cookers, can cut the cooking time down to 8 to 20 hours. Many tequilas are produced using autoclaves.

A diffuser is a piece of equipment that uses hot water to extract starches from shredded piñas. Running piñas through a diffuser takes about 4 hours, then hydrolyzation can be completed with cooking in an autoclave for 3 hours. Inexpensive tequilas with a bland, single-note flavor tend to use this method.

As you can imagine, the flavor of tequila will vary based on the hydrolysis method. It’s like comparing pork cooked for over 24 hours in an underground pit such as the traditional Mayan conchinita pibil or Hawaiian kalua pork vs. baking it in the oven for 4 to 6 hours vs. 1 hour in the Instant Pot.

Taste Tequila analyzed 48,345 ratings in their app to see how the method of production affected the taste and rating. (Read the details of the first section on “Cooking/Hydrolysis.”)

Acid Hydrolysis: State-of-the-Art Processing

Commercial agave syrup and low-grade tequilas are produced with acid hydrolysis using only a diffuser. This efficient industrial process can be completed in 3 to 4 hours, depending on conditions such as temperature and concentration of acid. Tequilas made this way are usually bitter and medicinal tasting and need additives to make them palatable.

While both sulfuric acid and hydrochloric acid are effective catalysts for hydrolyzing carbohydrates, sulfuric acid is the primary acid of choice in the production of agave syrup due to its higher efficiency and effectiveness. Sulfuric acid is a stronger acid and can provide a more rapid and complete hydrolysis of inulin, yielding a higher fructose content in the final syrup. As a side note, the use of strong acids can also introduce challenges related to waste disposal and environmental impact.

Enzyme Hydrolysis: Somewhere in the Middle

Enzymatic hydrolysis generally takes longer than acid hydrolysis but is often faster than heat hydrolysis. The processing time for enzyme hydrolysis can vary depending on the type of enzyme used, the concentration, and the desired degree of hydrolysis.

While enzyme hydrolysis offers higher specificity and milder conditions compared to acid hydrolysis, it can be more expensive than acid hydrolysis in large-scale production due to the cost of enzymes and longer processing times.

The High Fructose Syrup Connection: A Disturbing Resemblance

The shocking truth about agave syrup lies in its processing. Though claiming to be natural, agave syrup undergoes a highly refined process that draws eerie parallels to high fructose corn syrup (HFCS). Just like HFCS, agave syrup is hydrolyzed to create a high-fructose sweetener. This process concentrates fructose to alarming levels, presenting even greater health risks than its notorious cousin, HFCS.

While agave syrup and HFCS are derived from different sources, their manufacturing processes share significant similarities. Cornstarch is extracted from corn, then hydrolyzed to yield corn syrup comprised of mostly glucose. Historically, hydrolyzation was done with hydrochloric acid and some heat, though nowadays, enzymes may be used. Corn syrup can then be further processed into HFCS by enzymatically converting some of its glucose into fructose.

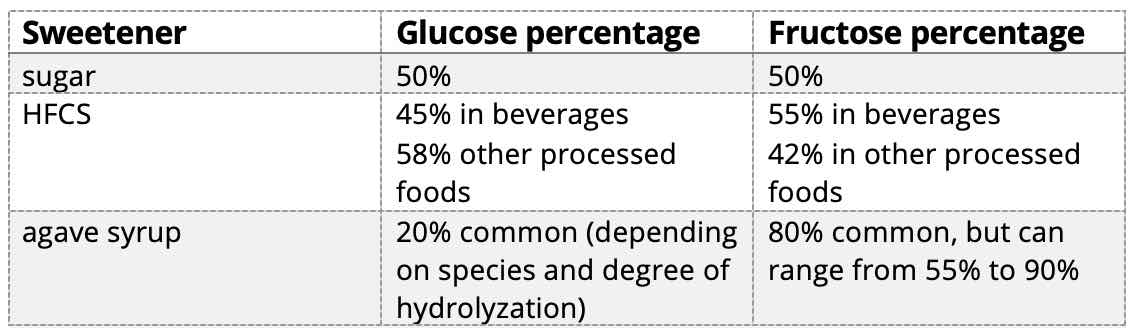

Agave syrup is often touted as a healthy sugar substitute because of its low glycemic index. Now reframe that seemingly healthy low glycemic index by examining the fructose content—agave syrup has the highest fructose content of any commercial sweetener, even more than HFCS!

Is high fructose syrup worse than sugar? Consuming high amounts of fructose can increase the risk of fatty liver, liver damage, high levels of triglycerides, and other metabolic disorders. Eating a few servings of whole fruit a day isn’t a problem—it’s the ultra-processed, concentrated forms of fructose that’s damaging.

Agave Healthy? It Boils Down to Time and Money

Agave syrup—is it healthy? While agave syrup might claim to be a product of tradition, the reality reveals a different tale. Collecting aguamiel for syrup production is labor-intensive and yields a small quantity. Depending on the agave species and growing conditions, it requires at least 5 to 15 years for the agave plant to reach maturity for flowering. Then there is a waiting period of at least 1 to 3 months for the plant to concentrate its sugars. Finally, the sap has to be collected by hand twice a day for several months. Thus, aguamiel collection is reserved for making pulque and not commercial agave syrup.

In contrast, hydrolyzing the piña to break down its complex carbohydrates into simple sugars is more efficient, aligning with the economics of mass production. When using heat hydrolyzation, the piñas have to accumulate enough complex carbohydrates, which means a minimum age of 5 to 6 years before harvest. Heat hydrolyzation can take between 7 hours to a week. Though faster and more efficient than aguamiel collection, heat hydrolyzation is more expensive than acid hydrolysis, so it is used for mezcal and tequila, not commercial agave syrup.

Due to its high efficiency, acid hydrolysis, which can be completed in 3 to 4 hours, can be used on agaves that aren’t mature or sweet—plants as young as 4 years old. This is the most efficient and cost-effective way to produce agave fructose syrup.

As we tread the path of nutritional choices, agave syrup's healthy facade crumbles to reveal a stark reality. The health claims that surround it mask a highly processed product, mirroring the pitfalls of high fructose corn syrup. The acid hydrolysis process and cost considerations further shatter the illusion of its wholesome origins. It's time to unmask agave syrup for what it truly is—a highly processed product marketed with a deceptive narrative.

Agave syrup highlights how the way a food is processed can matter as much as the plant it originally came from.

If you're interested in exploring how lifestyle patterns influence health more broadly, you can read more about how I work with people here.